I worked up a load for a Savage 110 (24" Barrel) in 7mm Rem Mag that initially didn't show any signs of pressure, either on the brass, primer or with heavy bolt lift. Now I am getting heavy bolt lift after only a few rounds and am hoping you guys can shed some light on the issue. The load is as follows:

Nosler Brass (once fired, bought new and fire formed), trim length 2.485"

Berger 168gr Classic Hunter

62.5 grains of H4831SC

O-give: 2.740" (0.012" off the lands)

Primer: Fed 215

My chronograph indicates this load is running about 2810 fps with a SD of 5.3. During load development, I shot all the way up to 64.0gr of H4831SC with this same bullet (0.5 grain increments) and it did not show any signs of pressure. Seating depth was done at 0.003" at a time starting at the lands and working back until it was 0.027" off the lands. The barrel was broke in as follows: 1 shot and clean for first 5 rounds, then 5 rounds and clean until 30 rounds, and then normal cleaning after that. Load development was 30 rounds at a time and never experiences pressure issues.

The above load shot a 5 round group of 0.248" at 100 yards for verification and then a 1" group at 300 yards. 600 yards it shot at 2.5". When I was verifying the load at 300 and 600 yards, I noticed I was getting some HEAVY bolt lift. There was probably 60ish rounds thru it at this time and I figured it was time for cleaning. I cleaned the barrel and chamber thoroughly using a copper remover, nylon brush and patches.

This morning, my wife and I took it out to foul the barrel with a couple of rounds and practice before she takes it for elk season next weekend. The first 4 rounds were fine, no heavy bolt lift or flattened primers. The 5th round had a sticky bolt lift and the 6th and 7th rounds were HEAVY bolt lift again. I searched the forum and other web information for possibly causes. The loaded rounds have a brass length at trim length, o-give consistent at 2.740". Other brass measurements (neck OD, shoulder length, web diameter, etc) are all within spec. I have my sizing die setting the shoulder back about 0.002". Loaded rounds chamber and extract without issue.

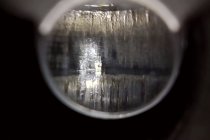

I cleaned the rifle again this morning and made sure the chamber was clean and had no solvents or oil left in it...as I read this can cause excessive pressure as well. I read the overall length of the brass can cause pressure...checked this and it is at trim length. I am stuck as to what could be causing this and believe it is either carbon or copper build up that I am not getting to when I am cleaning. The borescope will be here this Wednesday.

Can anyone shed some light as to what might be causing the overpressure after only 5 rounds thru the gun? Any help is greatly appreciated. Thank you in advance!

Nosler Brass (once fired, bought new and fire formed), trim length 2.485"

Berger 168gr Classic Hunter

62.5 grains of H4831SC

O-give: 2.740" (0.012" off the lands)

Primer: Fed 215

My chronograph indicates this load is running about 2810 fps with a SD of 5.3. During load development, I shot all the way up to 64.0gr of H4831SC with this same bullet (0.5 grain increments) and it did not show any signs of pressure. Seating depth was done at 0.003" at a time starting at the lands and working back until it was 0.027" off the lands. The barrel was broke in as follows: 1 shot and clean for first 5 rounds, then 5 rounds and clean until 30 rounds, and then normal cleaning after that. Load development was 30 rounds at a time and never experiences pressure issues.

The above load shot a 5 round group of 0.248" at 100 yards for verification and then a 1" group at 300 yards. 600 yards it shot at 2.5". When I was verifying the load at 300 and 600 yards, I noticed I was getting some HEAVY bolt lift. There was probably 60ish rounds thru it at this time and I figured it was time for cleaning. I cleaned the barrel and chamber thoroughly using a copper remover, nylon brush and patches.

This morning, my wife and I took it out to foul the barrel with a couple of rounds and practice before she takes it for elk season next weekend. The first 4 rounds were fine, no heavy bolt lift or flattened primers. The 5th round had a sticky bolt lift and the 6th and 7th rounds were HEAVY bolt lift again. I searched the forum and other web information for possibly causes. The loaded rounds have a brass length at trim length, o-give consistent at 2.740". Other brass measurements (neck OD, shoulder length, web diameter, etc) are all within spec. I have my sizing die setting the shoulder back about 0.002". Loaded rounds chamber and extract without issue.

I cleaned the rifle again this morning and made sure the chamber was clean and had no solvents or oil left in it...as I read this can cause excessive pressure as well. I read the overall length of the brass can cause pressure...checked this and it is at trim length. I am stuck as to what could be causing this and believe it is either carbon or copper build up that I am not getting to when I am cleaning. The borescope will be here this Wednesday.

Can anyone shed some light as to what might be causing the overpressure after only 5 rounds thru the gun? Any help is greatly appreciated. Thank you in advance!