Hi All,

Looking for some help on dimensions here...

I see the length for this is supposed to be 2.8".

I started reloading 10 years ago, doing .223 and .308 ... using lee dies\press

For 308 use, i had a savage 10, and the rounds i made were actually measuring 2.75"...worked perfectly in the gun.

Recently bought a savage 110 Storm 308, went to the range and had issues loading and ejecting!

Questioned my reloads...after checking things, the new rifle seems to have either a very tigh chamber or some issue...going back to savage... even empty clean shell case goin in the gun would cause a problem and come out scratched.

In the meantime, to confirm things, bought factory Federal .308, American white tail, 165 grain, to make some comparison measurments...

Those federal rounds are measuring 2.75" and not 2.8" ...

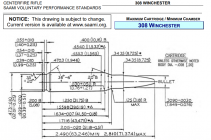

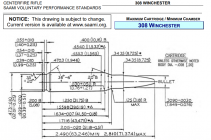

found some specs with mins and max measures..

from saami:

Question:

has anyone used is a min length for 308 down to 2.490"? a range from 2.7 to 2.8 seems acceptable.

Is this maybe gun dependent, or should all rifles in .308 be able to handle this range?

Thx

Looking for some help on dimensions here...

I see the length for this is supposed to be 2.8".

I started reloading 10 years ago, doing .223 and .308 ... using lee dies\press

For 308 use, i had a savage 10, and the rounds i made were actually measuring 2.75"...worked perfectly in the gun.

Recently bought a savage 110 Storm 308, went to the range and had issues loading and ejecting!

Questioned my reloads...after checking things, the new rifle seems to have either a very tigh chamber or some issue...going back to savage... even empty clean shell case goin in the gun would cause a problem and come out scratched.

In the meantime, to confirm things, bought factory Federal .308, American white tail, 165 grain, to make some comparison measurments...

Those federal rounds are measuring 2.75" and not 2.8" ...

found some specs with mins and max measures..

from saami:

Question:

has anyone used is a min length for 308 down to 2.490"? a range from 2.7 to 2.8 seems acceptable.

Is this maybe gun dependent, or should all rifles in .308 be able to handle this range?

Thx

Last edited: