MS50

Gold $$ Contributor

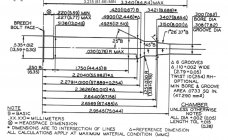

I'm in the process of rechambering a 308 to 6mmbr. The barrel I intend to use is 1:8, 26 inch, and has a .1163 freebore and a 3 degree throat angle. I understand that with this freebore I will be able to reload 100 class bullets with no issues. I've searched and haven't found specific information on what the 3 degree throat angle means to me. I want to start acquiring components for reloads. Does the 3 degree angle favor certain lengths and/or shapes or bullet? Thanks for any feedback or directions to a resource that will shed light on this.