I do not have a direct answer to your question. I can share my own experiences, which may be helpful.

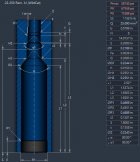

I don’t have my reamer print handy but my reamer pretty much matches up with the attached diagram. In fact every dimension I have the capability to measure does match the diagram as far as I can tell.

I have seen the associated terminology like “free bore,” “lead,” and such used having different meanings so I will just say the dimension “G” on mine is .200 inch.

My rifle is a 9 twist and the longest bullet I’ve shot is the Hornady 75 HPBT. With the bullet jammed into the rifling the cartridge base to ogive measurement is 2.108. The cartridge overall length is 2.502.

The bullet is .998 long which means my seating depth is .392. As you can see in the attached photograph, I could gain a little powder space, but not much, by seating farther our if I had a longer “G” dimension. I wish I had some of your bullets for comparison but I do not.

But here’s what compelled me to reply. It’s a long story but the short version is, I found that of the two brands of 22-250 brass I bought for fire forming and the two brands of factory ammo I got, the location of the neck-to-shoulder junction was .004 to in some cases .006 short of that point in the chamber, when set with AI go and no go gauges. As you probably know that’s how a 22-250 cartridge is supposed to head space in the Ackley Improved chamber. Of course the cartridges would chamber and go bang but my concern was the cases would stretch in the wrong place, leading to reduced case life. I think with your fire forming loads at 2.4 inch you may encounter this concern. What I did was seat my bullets long, firmly into the rifling when fire forming to hold the case head back against the bolt face so the shoulder would blow forward and out, rather than stretch the case back at the case head.

My concern would be getting a free bore so long it presents difficulty jamming some bullets for fire forming. But, my Hornady 75HPBT’s measure .600 from base to ogive. You may be able to measure your bullets BTO and compare to mine, and tweak that .200 “free bore” that I have to come up with an educated guess. My suggestion would be go with the .200. I THINK you would not gain a significant amount of powder space with the 80’s and 80.5’s with a longer free bore. Maybe you could for the 90 SMK, in which case a gunsmith could lengthen the free bore if you so desired after trying it with the .200 length.

View attachment 1538668View attachment 1538669