Lead Slanger

Silver $$ Contributor

I've had all my reloading equipment for seven or eight years now, but just now got around to getting a bench made, getting everything mounted and started putting it to use. So, as you can see, I'm a newbie. I went with a Lee 4 hole turret. I have five or six calibers I want to load for, but right now, I'm only working on loads for my 6.5 Creedmoor. A chronograph is next on my "have to get" list so I can get serious about finding the right load for my rifle. Until then, I'm just loading to shoot for groups.

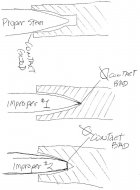

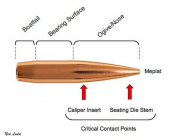

As you can see from the title, I'm getting inconsistent seating depths. Currently in the the press is a Lee Collet neck sizing die and a Lee Dead length seater die. I'm working with virgin Hornady brass, so no body sizing die needed at the moment. I do run them through the neck sizer, but I'll be honest, I haven't measured the neck tension. I don't think neck tension is the problem through. The components are virgin Hornady brass and Hornady match 140gr. BTHP's. I'm getting .005 variation between rounds. Being a machinist, I really want to spring for a competition micrometer die. It just makes sense. Until then, is there anything that I need to look for? I read where sorting bullets would help??? I'm measuring to the ogive, so I don't know what the base to ogive measurement has to do with anything.... Unless the bullets that much different where the seating stem is hitting them? Or would you think it would be the die? I also have a RCBS seating die that I haven't tried. If I were home right now, I would, but I'm not so I figured we could bench race about it. What do y'all think?

As you can see from the title, I'm getting inconsistent seating depths. Currently in the the press is a Lee Collet neck sizing die and a Lee Dead length seater die. I'm working with virgin Hornady brass, so no body sizing die needed at the moment. I do run them through the neck sizer, but I'll be honest, I haven't measured the neck tension. I don't think neck tension is the problem through. The components are virgin Hornady brass and Hornady match 140gr. BTHP's. I'm getting .005 variation between rounds. Being a machinist, I really want to spring for a competition micrometer die. It just makes sense. Until then, is there anything that I need to look for? I read where sorting bullets would help??? I'm measuring to the ogive, so I don't know what the base to ogive measurement has to do with anything.... Unless the bullets that much different where the seating stem is hitting them? Or would you think it would be the die? I also have a RCBS seating die that I haven't tried. If I were home right now, I would, but I'm not so I figured we could bench race about it. What do y'all think?