Dimner

I do believe in Captain Crunch.

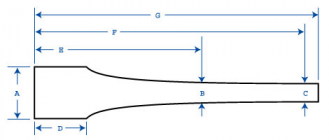

Just a quick question for you well versed fellas. I have a Tikka action that I would like to get a shilen barrel put on. Shilen's contour chart shows

If I'm reading this correctly, any barrel contoured by Shilen will be 1.220" at the shoulder?

My tikka action is smaller than that. My measuring shows the outside width at the face of 1.200". The factory Barrel shoulder is 1.125".

So my main question is, with a Shilen contoured barrel, I'm going to need to have a smith turn down that shank a bit so it doesn't look strange? So if that is the case, I may be better off just getting an uncontoured barrel and having the smith do the whole thing?

3 Sporter (.358 and smaller) | 1.220 | .815 | .625 | 2.5 | 6 | 24 | 26 | 3 lbs 7oz. |

4 Magnum Sporter (.375 and smaller) | 1.220 | .860 | .650 | 3.0 | 6 | 26 | 28 | 3 lbs 14oz. |

5 Lightweight Varmint | 1.220 | .910 | .700 | 3.0 | 6 | 26 | 28 | 4 lbs 8oz. |

If I'm reading this correctly, any barrel contoured by Shilen will be 1.220" at the shoulder?

My tikka action is smaller than that. My measuring shows the outside width at the face of 1.200". The factory Barrel shoulder is 1.125".

So my main question is, with a Shilen contoured barrel, I'm going to need to have a smith turn down that shank a bit so it doesn't look strange? So if that is the case, I may be better off just getting an uncontoured barrel and having the smith do the whole thing?