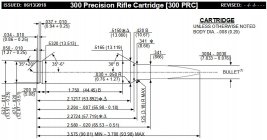

Is there anyone here who can help me learn to read SAAMI spec sheets?

I'm trying to figure out the headspace dimension of .300 PRC, from the case base to the datum line. I want to use my headspace comparator to measure my new Lapua brass against the SAAMI spec using my .420 bushing.

This drawing indicates 2.204" (so far, so good), but that's followed by - .007 (55.98 - 0.18). Anyone know what that second part means?

I'm trying to figure out the headspace dimension of .300 PRC, from the case base to the datum line. I want to use my headspace comparator to measure my new Lapua brass against the SAAMI spec using my .420 bushing.

This drawing indicates 2.204" (so far, so good), but that's followed by - .007 (55.98 - 0.18). Anyone know what that second part means?