You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ANNEALING

- Thread starter Webster

- Start date

Ideally you still need the hardness testing to design the algorithm which is used to back off from this point.

That makes sense to me. If the acute current change (or whatever change is being measured) coincides with the onset (or very close to onset) of recrystalization, all they have to do is back off a small amount to keep the case in recovery. It doesn't have to get back to an exact point, just far enough to not compromise the material's integrity. How far to back off I would guess was determined experimentally via hardness testing since I doubt there's any governing equations to calculate it directly.

The Temilaq 750 which is green needs to turn to another shade. This is very hard to tell if it is in flame as it will likely turn black instead first. At the point when the Templaq changes colour just below the shoulder the case is annealed. However taking it just 0.1-0.2 seconds further without it taking on any colour to the case is where I am aiming for.

How far to back off I would guess was determined experimentally via hardness testing since I doubt there's any governing equations to calculate it directly.

From AMP's website:

Once a sacrificial case is inserted and "Start” is pressed, AZTEC "Analyse” mode applies a continuous and precise amount of power to the targeted zone of the case until the exact instant that a datum point is reached. In general terms, the longer it takes to reach the datum, the greater the mass of brass in the targeted zone. The capture is extremely accurate and reliable. A patent is pending. By referencing the datum point, AZTEC calculates the correct annealing setting. The calculation, or algorithm, varies from cartridge to cartridge. Extensive laboratory micro-Vickers hardness testing has determined these algorithms.

We have speculated that the "datum point" is determined by monitoring current draw. There appears to be a sensor zip-tied to the ferrite core of the work coil - maybe they're monitoring something with this. Dunno.

Attachments

Last edited:

The Temilaq 750 which is green needs to turn to another shade. This is very hard to tell if it is in flame as it will likely turn black instead first. At the point when the Templaq changes colour just below the shoulder the case is annealed. However taking it just 0.1-0.2 seconds further without it taking on any colour to the case is where I am aiming for.

Support for - or dispute of - the above is what this discussion is about. Does the point "just below the shoulder" hitting 750F mean the case has been annealed? How far below the shoulder? Etc. About the only thing I am sure of is that anywhere above the lowest point down the case which hits 750F has likely hit a considerably hotter temperature.

I agree it is very hard to get a consistent heat over the area from the top of the neck to the place that you want to heat to below the shoulder. What i did find though that placing the case higher in the coil helped with this consistency and stopped the neck getting red and then that colour shooting down the neck. It also reduced that same change in the colour of the Tempilaq starting at the the top of the neck and shooting down quickly.

I aim for an amount down the case that gives a few mm below the shoulder neck Junction. Nothing like the distance you may see on Lapua brass. But even with a round work coil you will see that it is not a perfect line around the case, so I do just enough to make me feel good that, that junction is consistent.

I aim for an amount down the case that gives a few mm below the shoulder neck Junction. Nothing like the distance you may see on Lapua brass. But even with a round work coil you will see that it is not a perfect line around the case, so I do just enough to make me feel good that, that junction is consistent.

Their annealer already sets the brass back to the same hardness each time.

Not so much according to someone I know that has a hardness tester. He says the hardness goes all over the place. Does anyone else have readings form a hardness tester that show otherwise?

dgeesaman

Gold $$ Contributor

Not all hardness testers are created equal, especially for testing something like cartridge brass.Not so much according to someone I know that has a hardness tester. He says the hardness goes all over the place. Does anyone else have readings form a hardness tester that show otherwise?

The resin block / micro vickers tester that AMP contracted is specifically well suited for this purpose.

Not so much according to someone I know that has a hardness tester. He says the hardness goes all over the place. Does anyone else have readings form a hardness tester that show otherwise?

I thought I wouldn't comment on any of this but here goes.

Does anyone know who came up with 750F as the ideal annealing temp with a torch?

Is it possible repeated annealing has an accomulative affect. There seems to be an assuption that you always return to the same hardness. I don't know if AMPS covers this?

Alex Wheeler

Site $$ Sponsor

Will annealing give you smoother more consistent seating? Yes. Will that translate to better groups? Not always. In many cases a powder needs a lot of neck tension to give best results and annealing reduces that grip. In other cases a powder likes medium to light grip and annealed brass will shine. Test this before you anneal all your brass. Also, one thing I have seen with annealed brass is early pressure signs. The case has to spring back and if it doesnt because of annealing you can experience stiff bolt or clickers sooner than normal.

jthor

USAF Shooting Team

unless it’s a calibrated and certified HV tester, which I doubt, his tests are null and void unfortunately.Not so much according to someone I know that has a hardness tester. He says the hardness goes all over the place. Does anyone else have readings form a hardness tester that show otherwise?

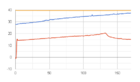

I did some tests to have a look at the current draw Vs time / heat into the case. What i found was that the current gradually increased during the heating process. Then for a very brief period it increased more than the previous linear ramp. Then it took a quick decrease. The last two phases which would be the critical data points for the Aztec happened very quickly.

As my annealer logs an displays the data while annealing, i tried a 300 win mag case to melting point.

this is the result:

X axis -> 1/10 sec

red -> drawn current

blue -> coil temperature

orange -> voltage

A clear maximum at melting point.

Will annealing give you smoother more consistent seating? Yes. Will that translate to better groups? Not always

No doubt, when it comes to results on paper, the story on annealing is far from written. It's easy to geek out on the science of it all but there's a lot of top shooters keeping 'em in the x-ring without it.

Does anyone know who came up with 750F as the ideal annealing temp with a torch?

I don't know the answer to that but I've often thought that given the imprecise temperature control with flame annealing, empirically (and with a little science sprinkled in) over time it may have just worked out to be a safe Tempilaq indicator temp that yields some softening without the risk of going overboard. Realistically, even using Tempilaq, with flame annealing I'd bet the true case temps well over shoot 750 because of how quickly temps are rising and instantaneous temp reading isn't really how Tempilaq is designed to be used. When I use it inside the case neck it pretty much seems to go immediately from nothing to charred which tells me it's likely well over 750.

As for "ideal annealing temp", I think that's still an open ended question at this point for among other things as Alex pointed out, there's valid reasons (and results to back it up) that maybe none of this dog and pony show is ideal

As my annealer logs an displays the data while annealing, i tried a 300 win mag case to melting point.

this is the result:View attachment 1120748

X axis -> 1/10 sec

red -> drawn current

blue -> coil temperature

orange -> voltage

A clear maximum at melting point.

Nice. That is staggeringly linear until just before the peak in conformance with what one would expect re resistivity vs temp. If you set the timer to stop right at that peak point what condition is the case in? Has it really melted?

20A @ 40V = a lot of power! The power supply (750W) most of us use for GinaErick implementations can't deliver that much power. Then again we're not trying to anneal in 1.3s either. (Albeit I now do think a shorter, higher burst of power is better than a longer heat time, so long as timing can still be reasonably managed.)

Do you have a current limiter? I wonder if the same profile occurs with lower current and longer time. I did not observe it on mine (limiting at 14.2A).

Last edited:

Does anyone know who came up with 750F as the ideal annealing temp with a torch?

Probably based on the Melting point of Zinc (787F). This was likely from a person who had ZERO understanding of alloys and how they function. Perhaps a denizen of a “hide” somewhere?

As we have discussed in the past, 750F gets not much but a stress relief.

Similar threads

- Replies

- 91

- Views

- 3,484

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.